Start or upgrade a production

line in 55 seconds.

The ResMark 5000 sets new standards for industrial product printing on absorbent porous surfaces such as cardboard, plaster, cellulose, or wood. It produces high-resolution prints up to 100mm in height and 300dpi , including barcodes.

This machine is optimised for the digitisation of packaging marking, providing unrivalled print image, with maximum availability and sustainability in mind.

Large Character Printer

ResMark 5000. The reliable workhorse.

Why The ResMark 5000?

High Resolution

This is the perfect large character inkjet printer for industrial product marking. High resolution - up to 300 dpi and a print height of up to a 100mm resulting in an exceptional high resolution print, making it an ideal replacement at a much lower cost than conventional labelling.

Printhead Distance

With an industry leading 12mm throw distance - leaves enough of a gap to prevent contact with passing product. Coupled with a retracting bracket, preventing the printhead from sustaining damage should this occur. This prevents unnecessary repair costs.

Maximum Uptime

With exceptionally quick installation set up, the ResMark is operational in as little as ten minutes. With an automatic cleaning function that keeps the printhead clean preventing manual intervention thus negating the need to stop production.

Easy Maintenance

The ResMark 5000 is designed with operative ease in mind. As such, the automatic cleaning function prevents operative interjection and the printheads are exceptionally easy to swap out thanks to a patented bayonet catch, meaning the printhead is ready to go in less than ten minutes.

Cost Savings

The empty cartridges can be disposed of in general waste preventing the need to use specialist waste disposal companies thus saving costs. Being manufactured from stainless steel reduces costs for replacement damaged printheads should that occur.

Sustainable

Having durable components and inks free from mineral oils, the ResMark is certified for the food industry as empty ink cartridges can be simply disposed of alongside general waste.

Customisable

The ResMark 5000 can operate with up to 8 printheads, future proofing your operation by minimising cost of additional printers as production output increases.

Large Character Printer ResMark 5000 For Marking & Coding

So, what can you do with the Large Character Hi Res, ResMark 5000 Printer?

Hitachi Continuous Ink Jet UX2

Print On Boxes & Plastics

ResMark 5000 marks cartons with product data, codes and logos in the highest quality and at high speed, whether card or plastic, due to a wide array of ink types.

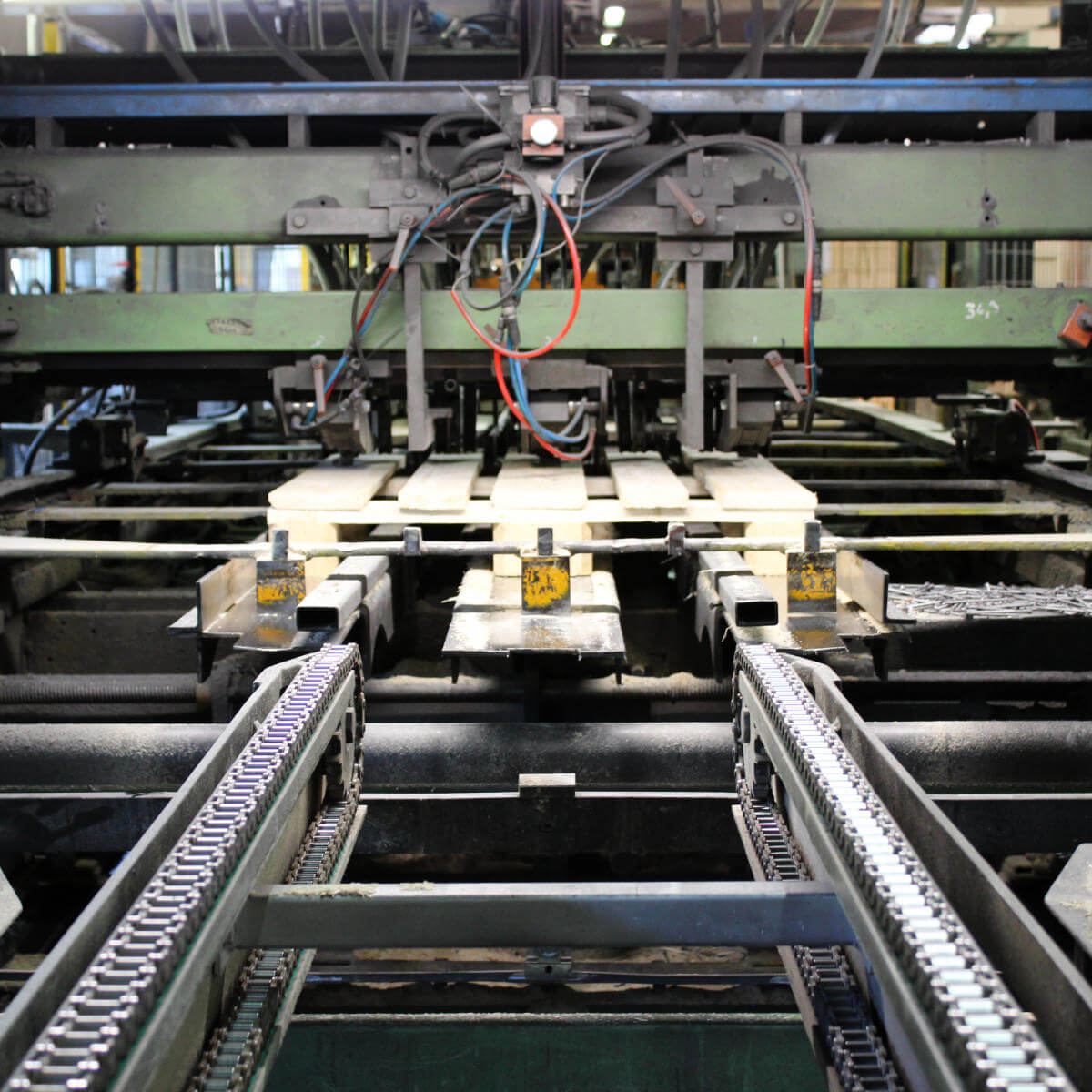

Print On Wood & Pallets

The marking of a wood and EPAL pallets at the highest speed and precision in an environment that most printers would collapse.

Remove Box Labels

With the ResMark 5000 labels can be removed due to printing direct onto substrate, saving on costs of label supply and backing disposal, notwithstanding saving on the environmental impact.

There are many different ways to integrate the ResMark 5000 into your production line. The WLAN network connection can be made directly via Loftware NiceLabel, i-mark's message management software.

The printer obtains the print images either directly from the ERP/MRP system or a connected PC or dedicated controller.

Should the ResMark 5000's printhead ever need to be repaired, it can be easily swapped with the patented bayonet lock.

Mineral oil-free ink assists with the sustainability giving it the lowest impact on the environment and our Scan-Mark ink is certified for use in the food industry.

With speedy installation, the printer is able to be used and production can continue, with minimal disruption. The ink re-circulation system ensures ink free of bubbles and leads to perfect imaging throughout every print.

In dusty environments, the automatic rinsing system continuously cleans the printhead to assure optimal printing results.

With a resolution of up to 300 dpi and a print image height of up to 100mm per print head (up to 8 print heads) your texts, codes and graphics have never looked sharper.

Want to see more from our customers?

Marking and coding

with real ROI.

Automated & semi-auto marking and coding machinery, end-to-end production lines that work with your packaging machinery.

All the techie bits.

All the technical specifications you may need. If you don't see what you're looking for below please message us. You will find all relevant documents on the ResMark 5000 right here.

Hot Stamp

Where it all started. The perfect solution where digital technology is not required.

How you can win with us

So, why use i-mark for marking and

coding solutions for your business?

Three steps to get the correct marking and coding solution for your business.

Email Us, Call Us or Send a Carrier Pigeon customerservice@imarkuk.com 01438 347 770

Meet with one of our advisors to discuss with you and your project team the challenges being faced today and considerations for the future.

Now we have found your solution and incorporated it, sit back and reap the benefits of maximised uptime, improved efficiencies and reduced costs.

We really do mean it when we say maximising uptime, increasing efficiency, while minimising costs.

German design and engineering

German engineering has for decades been the epitome of robustness, reliability and hi performance. Our systems in being of German manufacture are no different. This allows for a significant reduction in total cost of ownership due to extended equipment life. We have a customer base who commonly have machines over 15 years old in active use.

Minimising costs through message management

Incorrect coding on products leads to errors, whether it be, rework or costly penalties imposed by your customers. At i-mark we focus on holistic solutions that consider the technical capabilities of the coder, BUT also focus on understanding the information flow from planning to production. We then incorporate localised or centralised digitised solutions, thus eradicating human errors.

Next day delivery

Our UK based distribution centre, based in the Midlands, providing next day delivery of your consumables and equipment.

Same day service response

Nationwide network of qualified service technicians. Fully backed by technical help desk, local field service and dedicated customer service account team.

Have you seen our accreditations?

We mean it when we say we're 'experts'.

Our team possesses more experience solving problems in this field than any other. Nationwide network of qualified service technicians. Fully backed by a technical help desk, local field service and dedicated customer service account team. Nothing gets missed.